Cyrus wants to be a model.

Cyrus wants to be a model.

Dichroic glass is glass which can display multiple different colors depending on lighting conditions.

One dichroic material is a modern composite non-translucent glass that is produced by stacking layers of metal oxides which give the glass shifting colors depending on the angle of view, causing an array of colors to be displayed as an example of thin-film optics. The resulting glass is used for decorative purposes such as stained glass, jewelry and other forms of glass ar

In this post, I am making an art piece that I call Cattails at Night. There are several steps involved. It has three main parts, the cattail, the background, and the base. Each part requires cutting and firing. Some parts will need additional steps.

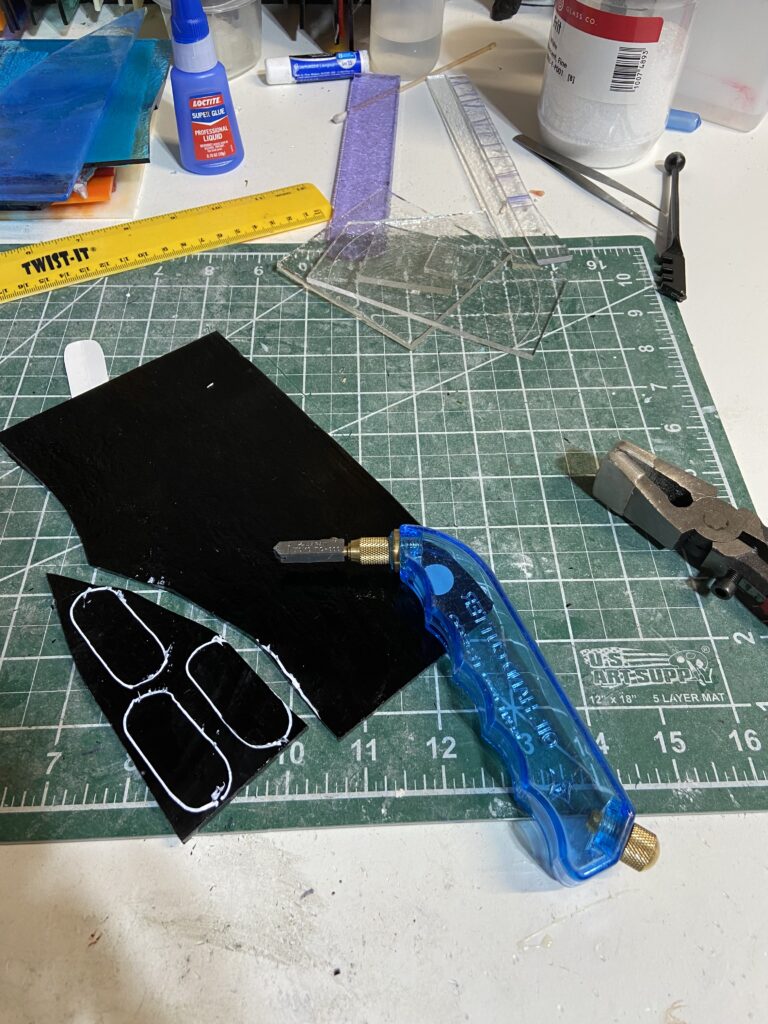

The first step is to find a piece of glass that will work with a project. In this case, I need a piece of black glass for the cattails.. I will start by cutting and shaping the cattails.

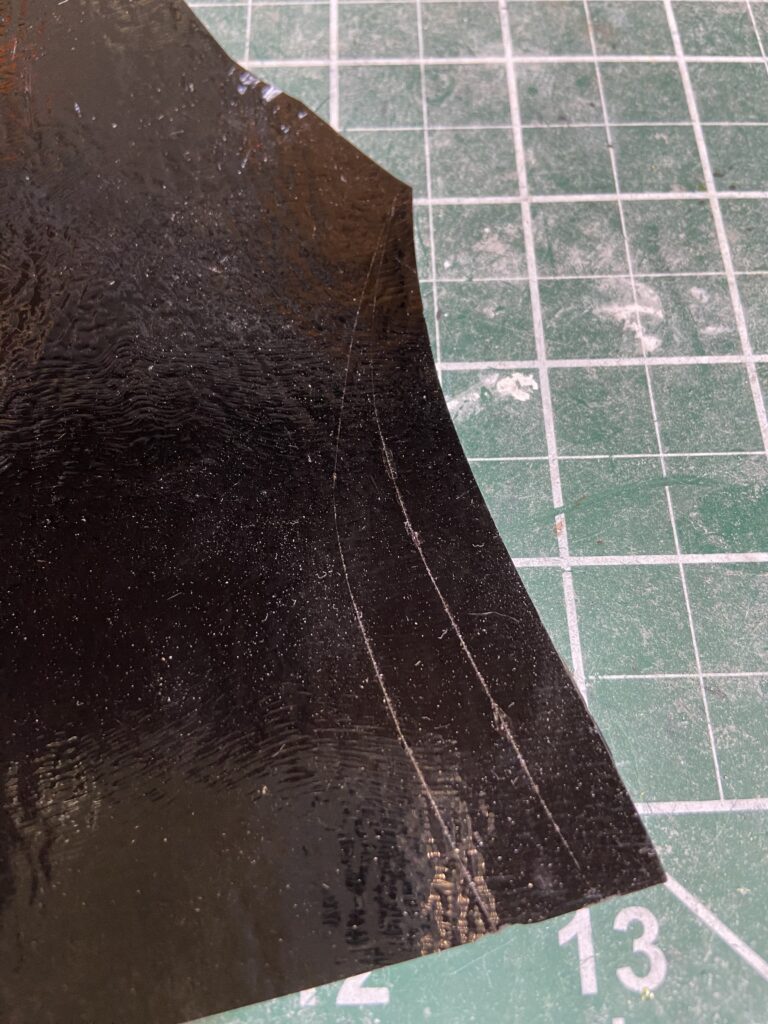

I traced a pattern for the body of the cattails and I cut them out. This a glass scorer. Once it’s scored, the breaking pliers are used to break the glass on that score (hopefully). This process is used for straight lines or gentle curves. The stems and leaves are cut into random sizes.

The next step is to refine the shape if needed. I will grind the cattail bodies to smooth them out.

I will place the cattail parts for firing in the kiln, they are heated to 1410 degrees for a contour fuse. This rounds the edges and fuses any overlapping pieces together. The heating requires a slow up and slow cool down, so it takes 24 hours.

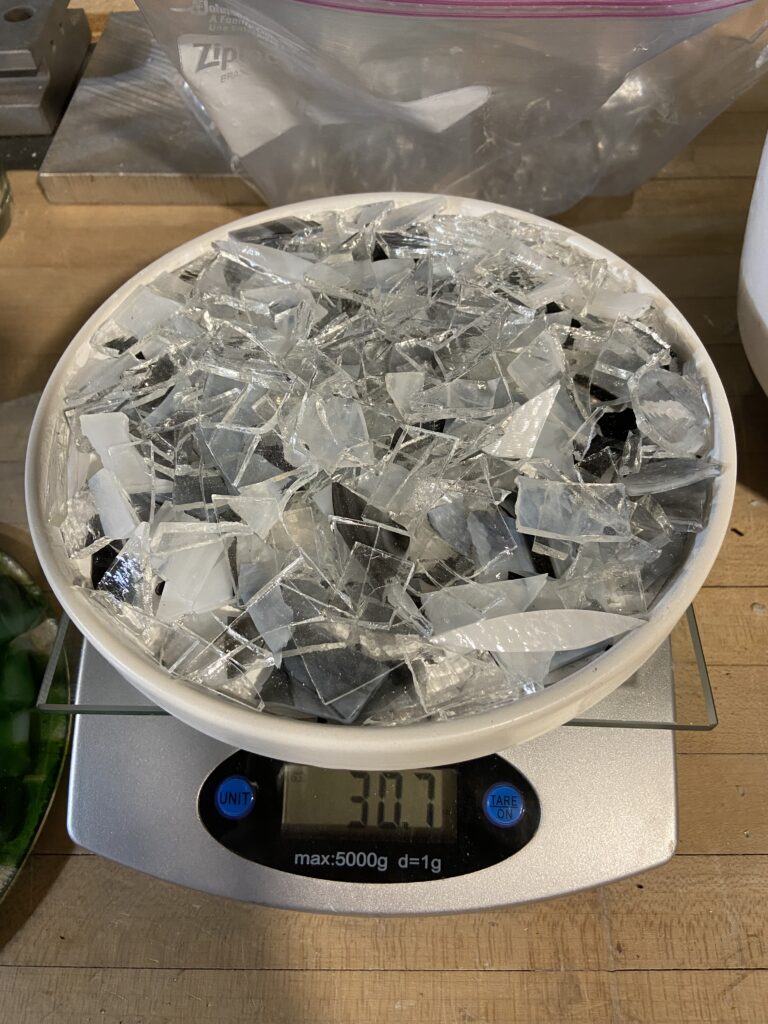

Next is the background piece. I will use chipped up glass arranged in a mold. I start with pieces of a variegated black and white glass. I’ll add some soft white and then top with clear. I want to keep the colors at different levels to show depth when it’s fired.

This will get fired in the Kiln to a full fuse, completely melted, at 1475 degrees. All firings need to heat slowly, cool down fast to 900 degrees, then hold for a length of time to ensure that the entire piece reaches this temp, then it can slowly cool to room temp. This firing takes 24 hours.

The next step is the stand for the glass. It is made with black glass cut into strips and placed so that the center opening will create a slot to fit the background piece. The pieces are laid in two layers that will overlap at the joints.

This requires a full fuse as described above.

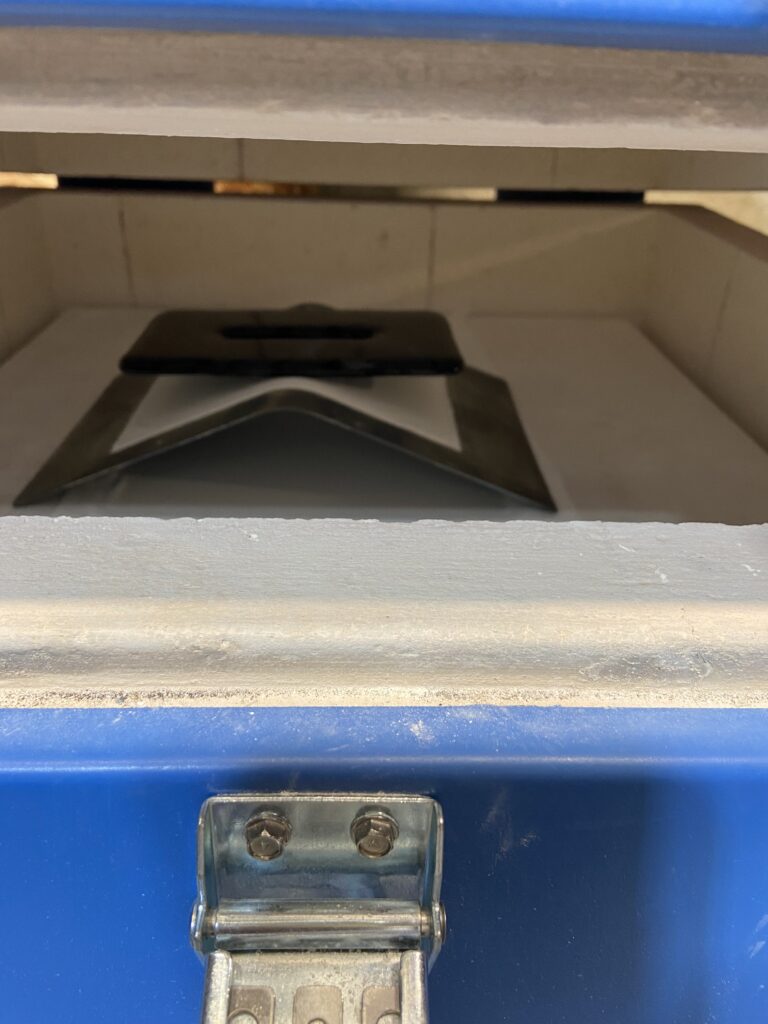

Once fused, the base is place over a stainless steel half round shape. It will be fired again to about 1200 degrees. It will be heated just enough to drape over the stainless steel mold. It’s important to keep the glass from melting enough to distort the base piece.

Now the fired cattails are placed on the background. They will be glued down so that they stay in place as I move them to the kiln. Then another firing. This one will be to tack fuse the glass at 1220 degrees. The goal is to melt the glass only enough for it to fuse together, but not enough to lose it’s texture.

This is the finished piece.